Fleet management KPIs (Key Performance Indicators) are crucial for the success of any business that wants to use data to improve the way their operation works.

But, with so many options out there, which KPIs are the most useful? And which are the most beneficial for fleet-based businesses?

In this article, we discuss the most important KPIs that fleet managers and finance leaders can use to calculate total cost of ownership (TCO), improve safety, and reduce costs throughout a fleet.

Table Of Contents

What Are Fleet Management KPIs?

Before we discuss specific fleet management KPIs that can help a business improve, let’s define the term “KPI” for clarity.

A KPI, or key performance indicator, is a measurement used to evaluate how well an employee, process, program, or business meets certain objectives for performance. Most often, these objectives are determined by a business as a way to improve some aspect of its workflow.

For example, if a business wants to reduce costs throughout their fleet (that’s their objective for performance), they may analyze key performance indicators such as:

- Budget adherence

- Fuel costs

- Fuel usage

- Vehicle cost per mile

By gaining insight into — and control over — these smaller aspects of their fleet, managers and finance leaders will be better positioned to change the workflow so that the larger aspect (the objective for performance) improves along the way.

Important Fleet Management KPIs To Track

1) Budget Adherence

An essential benchmark for tracking many of the metrics on this list is the KPI known as budget adherence.

All fleets need spending rules and an upper limit (a budget) to operate under, but how well are businesses adhering to that criteria?

If some part of an operation (e.g., a team, a department, a portion of the fleet) is only at or under budget two out of the twelve months of the year, that business may be better served reexamining how it allocates funds.

2) Vehicle Utilization

This fleet management KPI is an indicator of how well a business is using its mobile assets (e.g., vans, work trucks, semis, construction vehicles, etc.).

Vehicle utilization is most often calculated with the following formula:

Vehicle Utilization (as a percentage) = (Total Mileage Driven / Total Mileage Capacity) x 100

So, for example, if a single vehicle drives 10,000 miles in a month but has the capacity to do twice that (20,000 miles), the Vehicle Utilization is 50% ((10,000 / 20,000) x 100).

Vehicle utilization can also be calculated for the fleet as a whole by combining the mileage numbers for each vehicle and plugging the data into the formula above.

Doing so can help managers and finance leaders see if assets are being underused or if there’s a need to field more vehicles to meet the company’s logistical needs.

3) Vehicle Replacement Targets

Determining the best time to replace a vehicle can be a complex (and sometimes confusing) process.

Businesses need to get the most use out of their assets, but every vehicle sooner or later reaches a point of diminishing returns when the maintenance expenses equal or exceed the cost of a new vehicle.

Including vehicle replacement targets KPIs can help fleet managers see when it’s time to retire and replace one or more of their mobile assets.

4) Total Cost Of Ownership

Total Cost Of Ownership (TCO) is an extremely useful KPI that can help business administrators understand the true cost of fielding a fleet.

Total cost of ownership is calculated with the following formula:

Total Cost Of Ownership = Fixed Vehicle Costs + Variable Vehicle Costs

Fixed vehicle costs typically include things like lease payments, insurance, and permits, while variable vehicle costs include things like fuel, tolls, maintenance, and repairs.

5) Estimated Time Of Arrival

With the help of on-board telematics and GPS, a business can calculate and analyze each vehicle’s Estimated Time of Arrival (ETA).

Combining that KPI with route optimization and other metrics can help fleet managers plan how best to use mobile assets to get the work done efficiently, keep customers and clients happy, and maintain productivity and profitability.

6) Fuel Costs

Many of the fleet management KPIs on this list contribute directly to fuel costs businesses have to contend with on a daily, weekly, monthly, and yearly basis.

When fuel costs are below industry averages, there’s a good chance that a business is doing other things right (e.g., optimizing routes, keeping assets in good repair, and using vehicles to their full potential).

Alternatively, if fuel costs are above industry averages (or a business’s internal goals), it may indicate that changes need to be made or new technology adopted.

7) Fuel Usage

Tracking fuel usage can help finance leaders and business administrators detect when a fleet is consuming more fuel than usual (or that it has budgeted funds for).

This, in turn, may indicate the necessity to tweak some of the other KPIs on this list (e.g., route optimization, detrimental driving, and driver productivity) in order to bring fuel usage down to more manageable levels.

8) Vehicle Cost Per Mile

Vehicle cost per mile (VCPM) represents how much a business pays for each mile that an asset drives. This KPI demonstrates whether a fleet operation is cost-effective or is exceeding the budget that the business has established for all mobile assets.

To calculate vehicle cost per mile, take the Total Cost of Ownership (TCO) for a single vehicle (or the entire fleet) during a specific period (e.g., one month) and divide it by the total number of miles driven during that same period.

9) Preventative Maintenance Compliance

Preventative maintenance compliance measures the number of scheduled maintenance tasks that fleet mechanics (or third-party mechanics) have completed and compares them to the number of tasks left to do with the following formula:

Preventative Maintenance Compliance = (Completed Tasks / Remaining Tasks) x 100

The resulting number (a percentage) can help fleet management prevent unexpected breakdowns and improve vehicle safety, reliability, and lifespan — all of which can help businesses improve total cost of ownership and other major fleet management KPIs.

10) Average Vehicle Downtime

To calculate the average length of time that vehicles in a fleet are unavailable — the Average Vehicle Downtime — because of expected and unexpected issues such as maintenance, repairs, and accidents, use the following formula:

Average Vehicle Downtime = Total Downtime Of All Vehicles / Total Number Of Incidents

So, if a fleet experienced 10 unexpected incidents that led to 20 hours of total downtime, the average vehicle downtime would be two hours per incident.

11) Repair Costs

Tracking repair costs can help managers and finance leaders control, and even reduce, the total cost of ownership for a single vehicle or an entire fleet.

Including this fleet management KPI in the metrics that a business tracks regularly can help administrators identify trends in vehicle use and areas where they can make improvements.

12) Route Optimization

Route optimization — that is, planning or directing vehicles along the shortest, least congested, least expensive, and most direct route so they arrive safely and on time — is another useful KPI that fleet managers and finance leaders can use to control business costs.

Successful route optimization incorporates factors such as deadlines, driver proximity, fuel, number of stops, traffic, and approved routes and includes strategies such as static routing, dynamic routing, and real-time dynamic routing.

13) Safety Incidents Rate

The Safety Incidents Rate metric quantifies the frequency of safety-related events throughout a fleet-based business (e.g., accidents, traffic violations, near misses, etc.).

This fleet management KPI can help reveal how safely drivers are operating business vehicles, how well a business is maintaining regulatory compliance, and how efficiently an operation is running.

14) Driver Productivity

Driver Productivity measures the efficiency and effectiveness of a driver in piloting their vehicle and performing other business-related tasks.

The exact metrics that a business may choose to use can vary depending on the nature of the operation, but they often include quantifiers such as number of deliveries made, miles driven, or hours on the road per shift.

15) Detrimental Driving

Tracking detrimental driving such as speeding, extreme variable miles per hour, harsh acceleration, and heavy braking can help fleet managers lower fuel costs, control fuel usage, and reduce the need for expensive repair outlays.

16) Road Safety Compliance

The Road Safety Compliance KPI measures the extent to which drivers adhere to local, state, and federal laws and regulations (e.g., speed limits, seatbelt use, hours-of-service regulations, etc.).

Monitoring this fleet management KPI can help businesses prevent accidents, fulfill legal obligations, reduce costs, and ensure that drivers are following the rules of the road.

Tracking Crucial Fuel KPIs With Coast

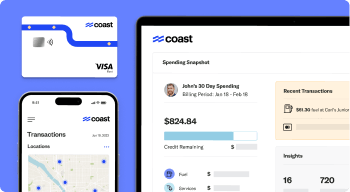

The Coast fleet and fuel card can help fleet managers and finance leaders get a handle on their fleet fuel expenses with tools and features, including:

- Open-loop functionality (accepted wherever you can use a Visa card)

- No-cap/no-minimum-spend rebates

- Real-time transaction reporting

- And much more

And, with Coast’s online platform, managers can see the details of every purchase right down to the line item so they can more accurately calculate total cost of ownership and maintain profits for their business in real time.

To learn more about how Coast can streamline fuel management, help businesses control costs, and improve fleet activities as a whole, visit CoastPay.com today.