Want to get the most out of business fleet vehicles? Create a preventative maintenance checklist for each one. Doing so will help the business preserve the appearance, safety, and operational capacity of its most important assets.

In this article, we discuss what goes into a good preventative maintenance checklist and give fleet managers and administrators a comprehensive example to get them started.

Table Of Contents

- What Exactly Is Preventative Maintenance?

- Benefits Of A Preventative Maintenance Checklist

- The Complete Preventative Maintenance Checklist

- Tips For Building A Preventative Maintenance Checklist

What Exactly Is Preventative Maintenance?

Preventative maintenance is the theory and practice of monitoring the condition of a vehicle and making necessary repairs before an issue spreads to other systems.

As the name suggests, preventative maintenance seeks to prevent the catastrophic — and more expensive — damage that can sideline a vehicle for days or even weeks. It basically comes down to spending a little now so the business doesn’t have to spend a lot later.

In many cases, preventative maintenance involves a lot of small checkups performed on a regular basis that keep the vehicle in good working order. That’s where the preventative maintenance checklist (or PMC for short) comes into play.

A comprehensive PMC tells drivers and mechanics exactly what they need to do — and when they need to do it — to maintain the safety and integrity of the vehicle.

Most PMCs are based on three important variables:

- Age of vehicle

- Total mileage

- Date since last service

Depending on what a fleet does on a daily basis, a combination of the last two variables will form the foundation of its PMC.

For example, a semi that is only in service three days a week will benefit more from a date-based PMC. If it’s put on a mileage-based PMC, many months may pass before it amasses enough miles to reach inspection triggers.

On the opposite side of the coin, a semi that is on the road six or seven days a week will benefit from a mileage-based PMC. If it’s put on a date-based PMC, it may amass double or even triple the recommended miles before the next inspection.

Benefits Of A Preventative Maintenance Checklist

Improved Vehicle Reliability

An effective preventative maintenance checklist can help improve vehicle reliability by reducing the number of minor issues that can take a car, truck, or van out of service.

That increased reliability allows fleet managers to maximize the asset’s availability and get the most use out of the vehicle as possible.

A record of reliability also allows drivers to have confidence in the vehicle itself and not to worry about breakdowns or other mechanical issues that might interrupt their workflow.

There are few things more irritating and disheartening to a driver than having to fix a minor issue (e.g., jump-start the battery or fill a tire that’s always leaking) on the vehicle they’ve been assigned before they can get to the main part of their job for the day.

Longer Vehicle Service Life

Another benefit of implementing a preventative maintenance checklist is a longer service life for each vehicle in the program.

Regular maintenance and repairs can help maintain the vehicle’s optimum operating conditions so that the wear and tear on each system is minimized. This increases the vehicle’s chances of functioning properly and safely for much longer than if that maintenance were to be neglected.

As a result, the cost of ownership goes down and the business can avoid breakdowns, major accidents, and premature failure of parts and systems that may cut short the useful service life of the vehicle.

Fewer Expensive Repairs

When businesses take a proactive approach to vehicle maintenance, they’ll be better able to find potential problems before they become worse, spread to other systems, and affect the entire vehicle.

This can help fleet owners avoid many of the sky-high expenses that come with large-scale repairs on integral systems.

For example, a pre-trip inspection, post-trip inspection, or service appointment using the preventative maintenance checklist may uncover a significant engine oil leak or transmission fluid leak.

The repairs for such leaks are relatively inexpensive and easy to perform. But letting the leaks go unaddressed may lead to significant damage and even catastrophic failure of either the engine or the transmission.

Those types of repairs can be extremely expensive and can impact the business’s bottom line in many ways.

Fleet managers can avoid expensive repairs by addressing small issues as soon as possible before they become large issues.

Improved Fleet Productivity

In fleet-based businesses, productivity is all about keeping the vehicles on the road and in good shape for as long as possible.

Regular maintenance makes it possible for fleet managers to increase productivity in many forms, including:

- Fewer disruptions to the workflow

- Better vehicle performance (both in the short term and the long term)

- Adherence to schedules

- Timely deliveries

- Satisfied customers

- Improved driver moral

Businesses can also realize improvements in revenue and work hours when they prevent the loss of money and time that come with towing vehicles and completing repairs after a breakdown.

The Complete Preventative Maintenance Checklist

After looking over this general checklist, managers should go through the owner’s manual for each different type of fleet vehicle and incorporate the advice into the process. Every vehicle is different, and each owner’s manual will have specific service recommendations based on mileage or age.

For example, work trucks may need to have their U-joints greased once a year or every 5,000 miles, while work vans may need that same type of service every two years or 10,000 miles.

If the business operates semis, they may need to have their U-joints greased even more often because of the heavy loads they pull. It all depends on what the original equipment manufacturer (OEM) suggests.

Once there’s a PMC in place for each type of commercial vehicle (e.g., Ford Transit, Ford F-350, Kenworth T680), managers and mechanics should tweak the details for each individual commercial vehicle (e.g., Ford Transit #1, Ford Transit #2, Ford Transit #3).

Depending on how they’re used, individual vehicles will develop their own unique needs. For example, Ford Transit #1 may do well on the manufacturer’s recommended oil change schedule, while Ford Transit #2 may need more frequent oil changes.

Fleet administrators shouldn’t be afraid to alter the preventative maintenance checklist below if they find that something else works better for a particular vehicle.

Daily Preventative Maintenance Checklist

Implementing a daily maintenance checklist is one of the best things a fleet-based business can do to keep its commercial fleet in good working order. It only takes a few minutes to complete and helps get drivers familiar with the various systems of the vehicles they’ll be operating.

Before heading out on the road for the day’s runs, drivers should:

- Walk around the vehicle looking for anything that’s out of place

- Check for body damage

- Examine the tires for uneven wear

- Verify that the tires are inflated to the right pressure

- Put air in the tires if need be

- Look under the vehicle for fluid leaks (i.e., wet spots on the ground)

- Examine the engine for fluid leaks (i.e., wet spots where they shouldn’t be)

- Visually check for wear on the fan belts

- Check the oil

- Verify that engine coolant is at the proper level

- Check windshield washer fluid

- Inspect the brake linings

- Verify that the turn signals work

- Verify that the brake lights work

- Verify that the hazard lights work

If any of the fluid levels are low, drivers should know the proper procedure for topping them up.

This may seem like a lot at first, but the majority of the steps are quick visual verifications that only take a few seconds to complete.

Once the vehicle is running, warmed up, and ready to go, drivers should verify that the gauges on the dashboard (e.g., fuel level, oil pressure, engine temperature, transmission temperature, etc.) are all within acceptable levels.

If the driver discovers an issue while going through the daily preventative maintenance checklist, they should report it to the fleet manager or fleet mechanic immediately.

Monthly Preventative Maintenance Checklist

From here on out, the preventative maintenance checklist contains some form of the previous milestone plus other tasks. This helps the business ensure that the essential systems of the vehicle are always working properly.

In most cases, the monthly PMC can be performed by the driver as part of their pre-trip walkthrough so the vehicle doesn’t have to be taken out of service for a trip to the mechanic.

- Check the air conditioning

- Check the heater

- Inspect the engine and cabin air filters

- Fill coolant if necessary

- Check engine oil (fill if necessary)

- Change lightbulbs on exterior lights that are malfunctioning

- Check tire pressure

- Top up windshield washer fluid

- Examine windshield wipers and replace if necessary

- Inspect wheels and rims for damage

If drivers find issues with systems such as the air conditioner, heater, or windshield wipers, fleet managers may choose to send them out anyway — depending on the weather for the day — and then take the vehicle out of service when they return.

If, however, drivers find issues with the air filters, fluids, lights, or wheels and rims, it’s best to switch vehicles so that the problem doesn’t spread to other systems.

Quarterly Preventative Maintenance Checklist

From this point forward, preventative maintenance checklists should be conducted by a trained fleet mechanic so that everything stays in tip-top shape.

- Inspect automatic transmission for cracks, loose brackets, and missing bolts

- Clean corrosion on battery terminals

- Charge or replace battery

- Repair any body damage

- Replace cracked, frayed, split, or glazed belts

- Replace cracked, nicked, or bulged hoses

- Check power steering fluid

- Examine undercarriage and frame for damage

- Change engine oil

- Inspect windshield for chips and cracks

As fleet mechanics run this PMC, they should keep an eye out for other issues that aren’t on this list and to address those problems on an as-needed basis.

Depending on what the technician finds during the quarterly PMC, vehicles may be out of service for anywhere from a few hours to a full day.

Biannual Preventative Maintenance Checklist

Every six months, mechanics should run a biannual PMC in addition to the quarterly PMC. Steps in this portion of the checklist include:

- Check and fill brake fluid

- Inspect brake pads, liners, and master cylinder

- Test main and auxiliary electrical systems

- Check exhaust system for leaks and noise from under the exhaust manifold

- Examine seat belts for frays or other damage

- Test horn

- Check pressure on spare tire and examine for leaks

- Test shock absorbers

- Test wheel bearings (listen for snaps, click, pops, or grinding when wheel is spinning)

- Check wheel alignment

The biannual PMC is more involved than the quarterly version, so vehicles will likely be out of service for at least a day — maybe two or three depending on what the technician finds.

Annual Preventative Maintenance Checklist

At least once a year, vehicles should be subjected to a comprehensive inspection that includes everything from the previous checklists as well as:

- Check and tighten engine mounts

- Examine the steering and suspension systems

- Rotate or replace tires

- Lubricate all grease fittings including U-joints

This stage of the PMC is usually more involved than the other stages because it includes inspections of some of the large, more complex systems. Because of this, the vehicles may be out of service for anywhere from two days to a full week.

Tips For Building A Preventative Maintenance Checklist

Establish A Baseline

It’s always a good idea for business owners to establish a baseline for the condition of their vehicles so that fleet managers know how to move forward.

Fleet mechanics should run through a full inspection and diagnostic and document the state of each system on the vehicle before putting it into service (or back into service).

Such reports should include:

- Vehicle utilization

- Fuel efficiency

- Maintenance and repair history

- Replaced parts

- Fluid levels

- Mileage

With such a baseline in place, fleet managers and mechanics can then monitor the asset and build the best preventative maintenance checklist for that particular vehicle.

Include All Vehicle Systems

When deciding which tasks need to be performed at specific times, businesses do well to include an inspection of all systems every time the checklist is performed.

Just how deep into the system the technician goes depends on a variety of factors, but they should, at the very least, perform a visual examination of all major components every time they get under the hood.

For example, an effective preventative maintenance checklist may include a brake fluid flush every six months. That doesn’t mean that the daily, monthly, quarterly, and annual checklists ignore the brake system completely.

As mentioned, each of those checklists should include at least a brief visual inspection and basic test of the brake components as long as the vehicle is in service.

Including all systems on every checklist can help prevent high-wear-and-tear components from going uninspected and breaking down before their time.

Separate Necessary Tasks From Unnecessary Tasks

Depending on which stage of the preventative maintenance checklist each vehicle is in, it may be important to separate necessary tasks from unnecessary tasks so that drivers and mechanics understand exactly what needs to be done.

For example, the annual PMC typically contains an entry for rotating or replacing the tires. In some cases, it may be more effective to replace rather than continue rotating.

This decision — that is separating the necessary from the unnecessary — often comes down to a cost analysis that reveals specific data, including:

- The expenses the business is trying to prevent by performing the maintenance

- The cost of the maintenance versus that of the damage that could occur

With such data in mind, fleet managers will be better positioned to design effective and efficient PMCs that don’t waste resources on unnecessary tasks.

Decide Who Will Perform Each Task

Though both drivers and mechanics may have access to all the preventative maintenance checklists, it’s important that fleet managers designate who will perform each task.

Daily PMCs can be conducted by drivers and, in many cases, those same drivers can perform the monthly PMC for any vehicles they are assigned to operate.

After that, however, and depending on the ability, skill, and knowledge of each driver, managers may decide that all quarterly, biannual, and annual PMCs should be conducted by a qualified mechanic.

Create Clear And Concise Task Descriptions

An important hurdle in building an effective preventative maintenance checklist program is writing clear, concise, and logical task descriptions.

Tasks should be arranged in an order that lends itself to quick inspection — not requiring drivers to go from under the vehicle to the cab and back multiple times.

Similarly, each task description should be as complete as possible without being overly long and difficult to read.

That said, fleet managers should include these basics on the PMC:

- The system being examined

- What to do within each system

- How to do it

- Where to look

- Tools needed to do the job successfully

Fleet admins should review the PMCs on a regular basis — even asking for driver and mechanic input — and revise each task description to be as effective and instructive as possible.

Train Drivers On Each Task

Fleet managers shouldn’t assume that every driver knows how to perform all the tasks on PMCs. And, even if they do know how to do everything, they might not be doing it according to the business’s high standards.

To avoid such mistakes, the business should set up a program to train drivers in the tasks they’ll be asked to perform in the course of their daily work.

Core components of this training include:

- Brakes

- Tires

- Fluids

- Electrical

The training should also include details to look for that indicate a problem with these essential systems and what the driver should do if they find an issue.

Create A Preventative Maintenance Checklist For New Vehicles

As we mentioned, it’s important to establish a baseline for all new and existing vehicles in the fleet. To help mechanics in the process, fleet owners should create a preventative maintenance checklist for new vehicles.

Often, this type of PMC is little more than basic inspection and reporting rather than actual replacement and repair of components.

Why perform such inspections if the vehicles are new?

Because not all vehicles will arrive at the business in perfect working condition. Abnormalities may exist that can quickly develop into larger problems once the asset is on the road.

Inspecting each system before putting the vehicle into service makes it possible for mechanics to address these abnormalities, log important information, and acquire data that can help them build a baseline for the “standard operating condition” of each car, truck, and van in the fleet.

Monitor Maintenance And Performance Metrics

No preventative maintenance checklist system will work unless everyone involved — fleet managers, admins, drivers, and mechanics — monitors the metrics for each vehicle and takes action when necessary.

Similarly, management should use the data that each PMC provides to analyze the fleet and obtain insight into such aspects as:

- Preventative maintenance versus unscheduled repairs

- Money spent on preventative maintenance versus reactive repairs

- Years a vehicle has been in service versus its average lifespan

These aren’t the only metrics that businesses should analyze, but they can go a long way toward helping everyone on the team get the most out of each vehicle in the fleet.

Streamlined Fleet Management

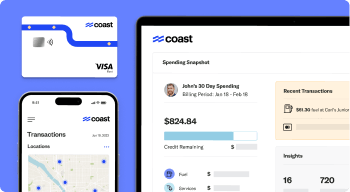

Regardless of what a business’s preventative maintenance checklist looks like, one of the best ways to streamline fuel and fleet management is with Coast.

Coast provides real-time expense tracking and a powerful online management platform that puts the entire fleet in the palm of the fleet manager’s hand and provides full visibility of every dollar spent.

With Coast, fleet owners and managers will enjoy:

- Easy manager access

- Comprehensive spending controls

- Universal acceptance

- Customer service they can count on

- Advanced security

- Data tracking and reporting

For more information and to learn about everything Coast can do for fleet-based businesses, visit CoastPay.com today.